Amanda Morglund makes clothes from mushroom fabric

Words by Maeve Kerr-Crowley

Fungi fashion.

If I told you there was a network of guerrilla mushroom growers operating at the frontier of Australian fashion technology, I wouldn’t be surprised if you didn’t believe me. Which is fair enough, because it sounds like the B-plot of a bad ’80s sci-fi film.

But sometimes life is, indeed, stranger than fiction.

Though fruit and veggies have been pushing their way to the front of the sustainable fashion movement for a while (with innovative designers using everything from vegetable-based dyes to pineapple leather or algae textiles), mushroom technology is the newest and arguably most impressive innovation in the field.

Fashion designer, Amanda Morglund, is the subject of Mycelium Made, a short film premiering at this year’s Environmental Film Festival Australia explaining everything about the material. In just five minutes, Amanda will run you through the process of turning scraps of textiles destined for the bin into usable, biodegradable materials.

Though Amanda’s background is in fashion, not science, she learnt two life changing things while completing her degree.

The first was just how much fabric is wasted in the design and production process. The second was that other industries were already using materials cultivated from mushrooms to cut down on their environmental impact – she cites insulation wall panels as one of the earliest uses of mushroom technology – which led her to consider their potential use in fashion.

A mushroom’s digestive system is adaptable enough to eat pretty much anything you throw at it, which means it can break down toxic or non-recyclable chemicals within the materials it’s grown on.

The process is simple and starts with any piece of waste fabric Amanda has on hand. Because they’ve naturally developed to be so adaptable, mushrooms will grow on just about anything – think sawdust, cardboard, petrol and cigarette butts.

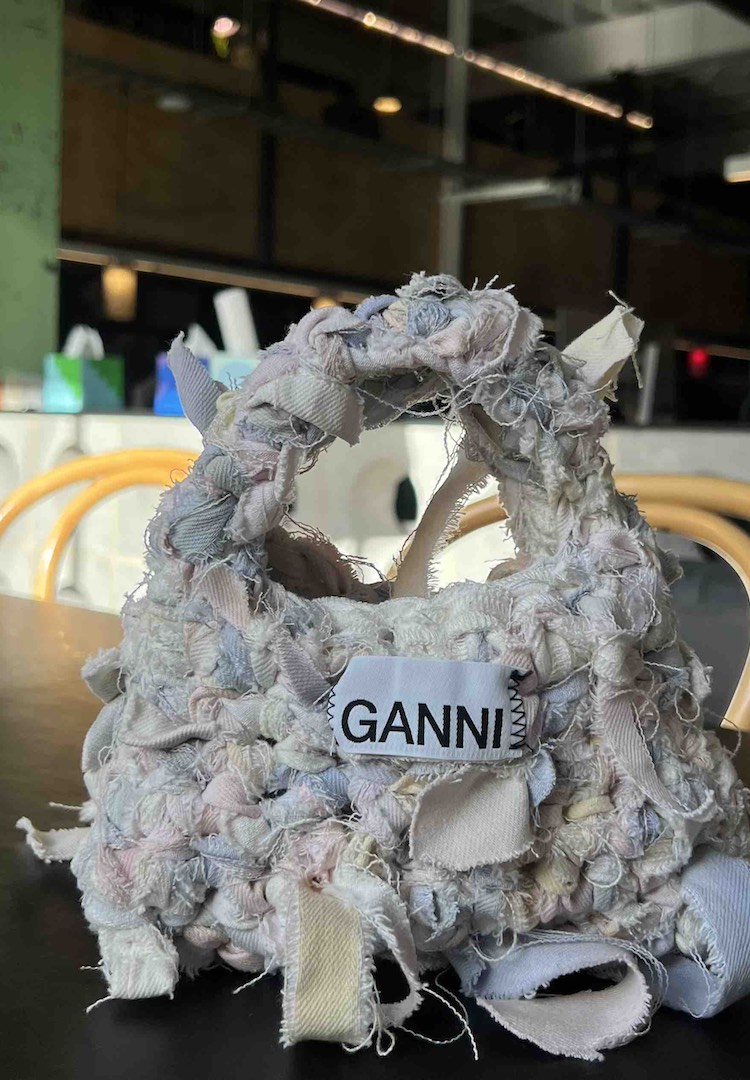

Then she takes a tiny piece of a mushroom’s root system, called mycelium, adds it to her textile and lets nature work its magic. The root network infiltrates the base material, binding with its fibres, digesting chemicals and creating a whole new textile. Once the surface has been completely taken over, mushrooms start to sprout. But then these sprouts are removed, the textile is dried out, and she’s left with a sheet of mushroom roots that mimics regular fabric. The whole process takes about four to six weeks.

“You can basically use any mushroom,” says Amanda. “I’m using some really accessible types like oyster mushrooms, which lots of people can buy at the grocery store.”

In fashion, these cultivated textiles are particularly useful as a replacement for internal, synthetic padding structures (like shoulder pads, if that’s your style) which aren’t typically recyclable or biodegradable.

As well as making these garments more easily disposable at the end of their time in your wardrobe, mushroom textiles are moisture wicking, self-insulating, and often more flexible. They also don’t require any chemical tanning, which makes them less environmentally hazardous and much quicker to produce than something like leather.

“A lot of people don’t really know what to do with all the waste products that come through our houses,” Amanda explains. “So I really encourage people to grow mushrooms on all their cardboard and leftover textiles before they consider throwing them out.”

She mentions a widespread community of DIY cultivators running groups and producing guides to help others get started growing their own mushrooms. Due to the accessibility of mushrooms, cultivation materials are available and affordable online. Add to that the versatility of base materials you could grow your shrooms on, and you’re looking at no big start-up cost for a potentially huge environmental payoff.

In fact, the ‘lab’ setup seen in Mycelium Made is just a dressed-up room in Amanda’s apartment.

“There’s a great sense of hope around it because it is so accessible. You could pick up rubbish locally and grow your mushrooms on that. Or clean up a beach and use that as your cultivation point,” Amanda suggests.

Because she’s still first and foremost a designer, Amanda has made mushroom textiles the foundation of a collection she has in the works. Set to be finished in 2020, the range features internal structures made from cultivated fabric and recycled silks and cotton as exteriors. Every piece is tailored by hand and heavily embroidered, making the collection a time-intensive labour of love.

In the meantime, Amanda is also exploring new ways to use her mushrooms’ powerful digestive systems outside of fashion. Two particular areas of interest are in breaking down chemical or oil spills and strengthening a strain of mushrooms she uses to tackle cigarette butts.

“We don’t have any way to handle cigarette butts from a waste management perspective,” she explains. “They’ve got so many chemicals and mixed materials, so there’s no good way to break them down. But my mushrooms will happily digest them and everything in them.”

Catch Amanda and her miraculous, cigarette-munching mushrooms at the Environmental Film Festival Australia on October 31. Tickets are available here.